Ancient processes met new technologies when Rab Maclure, Director of the MFA in Design at VCU in Qatar brought eighteen post-graduate design students to the Glass Hub for their annual field study trip, an ‘immersive learning experience’. VCUarts Qatar, (Eastern Arabia), is the Qatar campus of the prestigious Virginia Commonwealth University School of the Arts, USA.

This unique opportunity transpired, when Rab Maclure discovered us online, and, impressed by our course programmes, asked us if we would consider hosting an experimental mould-blowing project for his students. The project was to design and make fifty-four led lamps and involved a variety of technologies including 3D printing, metal casting, glassblowing and LED coding – across three continents!

Rab wanted to work with us in the UK to facilitate the making of the fifty-four lamps (three for each student) as part of their MA product design syllabus. This included many processes: digital designing; 3D printing; glassblowing; glass cutting; electrical wiring; LED coding and assembling. The new technologies of 3D printing, wiring and LED coding, working alongside the ancient art of blowing molten glass.

Of course, we said “YES!” and with the project given the go-ahead, it was then sketched out by phone, skype, email and WhatsApp. Our main focus was to organise the part where students blew molten glass into their individually designed 3D printed metal moulds but there was more. The brief was to get students to complete three lamps each, but also teach them about the properties of glass in all stages and techniques. It was to be a full immersion into a host of glassmaking processes …which is what we do best at The Glass Hub.

The team members were Helga, two of our core glassblowing tutors Sonja and Bliss, myself – KT, and of course, our new interns Lolita and Bailey. To ensure this project worked, we also needed the expertise of someone who was familiar with both glass and 3D printing, coding and wiring to bring together old and new technologies. Look no further than a past student of ours with an extraordinary mind, Robin. Having taught him on our Glass Hub Foundation Course, we knew he had excellent knowledge of glass, but more importantly, was familiar with the technologies we needed. Robin worked with the students to develop a custom code for the lamp’s LED controller, which used a phone app to control the lights and he also helped debug any tech issues. His computer science knowledge with coding and LED ‘hacking’ joined the parts of this complex education jigsaw together, and it all finally fell into place.

Day 1 - Monday

Monday arrived and we waited to welcome all the students from their weekend spent in London, their 3D printed metal moulds and plastic lamp bases having arrived from Shapeways in Belgium. The furnaces were hot and full of molten glass, moulds were hinged together, the catering sorted, tutors ready and anticipation high! Robin had already used his 3D printer to produce some transparent plastic replicas of the students designs to give a 3D visual idea of the glass pieces they would create. The metal moulds (negatives) were incredible works of art in themselves. These were created in 2-part, 3D printed in a bronze and stainless-steel alloy, perfect to blow glass into. Even the British weather with November wind and rain (very different to Qatar!) did not deter the excited students.

For the duration of the project, we split the students into three groups of six. They then took turns in three areas:

- Hot glass mould blowing

- Cold-working and LED programming

- Lampworking, fusing and troubleshooting

10am – after a warm welcome we began with a stringent health and safety brief and a careful induction on how to use potentially dangerous pieces of equipment. Glass is either hot, sharp or requires a big motor or spinning blade or wheel! The hot shop in particular, was a highly charged, noisy and exciting place to be. Great care was required to ensure the students did not burn themselves or others. Sonja, Bliss and Bailey, taught the students a formula – like dance instructors, they had to work as a team, and a certain choreography was required for the sequence of timed glass blowing movements. Primarily, we used clear glass, focussing on getting the technique right. Basic training from Bliss, allowed the students to get a feel for this hot, molten material, while Sonja worked one-to-one to create each and every one of the eighteen moulds, with their respective designers, individually.

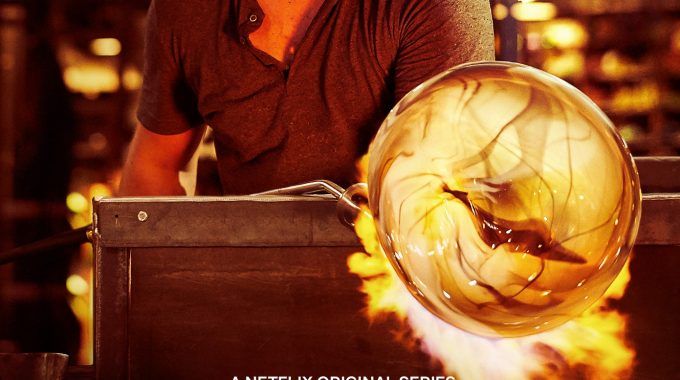

Hot Glass Mould Blowing

As soon as the mould was in place, hot glass was gathered from the furnace. The glass was then blown into the moulds – a rapid and efficient process that snapped everyone into action. Students were jumping up onto the bench and blowing air into the expandable molten material nestling inside their two-part metal moulds. This process was the defining factor that changed the worlds’ conception of glass. When the Romans discovered mould blowing almost 2,000 years ago, glass went from being as precious as gold, to a utilitarian object. Today’s environmental crisis is yet again redefining glass as an object of worth, as it lasts up to 2000 years, and is not throw-away.

As soon as the mould was in place, hot glass was gathered from the furnace. The glass was then blown into the moulds – a rapid and efficient process that snapped everyone into action. Students were jumping up onto the bench and blowing air into the expandable molten material nestling inside their two-part metal moulds. This process was the defining factor that changed the worlds’ conception of glass. When the Romans discovered mould blowing almost 2,000 years ago, glass went from being as precious as gold, to a utilitarian object. Today’s environmental crisis is yet again redefining glass as an object of worth, as it lasts up to 2000 years, and is not throw-away.

Cold Working (finishing techniques)

Mould-blowing doesn’t produce a finished piece. Excess glass material – ‘overblow’ needs to be removed along with other surface preparations known as cold-working. Students were shown a variety of techniques such as sawing the “overblow” glass away; grinding excess material on a flatbed grinder and polishing using the linisher. They also learned how to drill, cut and introduce pattern to the surface using the lathe. Sandblasting was another technique where students could introduce graduated diffusion for their lamps. We supplied some ready-made coloured glass that the group could experiment freely on.

Lampworking

Sarah held the focus of the students as they learned the ancient process of making glass beads on a mandrel (small metal rod) using a torch flame – glass making in miniature! Students were shown how to make various glass beads, with a variety of different effects, patterns and shapes. It was a chance for each group to take time out from working on their products and enjoy making and learning a new skill set. This had the added benefit, of allowing these creative students to make jewellery for family and friends at home in Qatar!

Day 2 - Tuesday

There was great excitement in the morning to open the Lehr, the kiln in which yesterday’s glass had cooled down slowly overnight and see all of the glass trial pieces. Each group discussed what had worked, what didn’t work and effects that inspired or confused the design concept. We discussed colour techniques and combinations of colour designs. The students were starting to gain more confidence in the hot shop, understanding the different stages, processes and technical terms. They were now discovering how distracting colour can be. Glassblowing has so many possibilities and potential colour techniques, it can enhance …but can also distract.

Glass Fusing

Students learned how to cut sheet glass by hand and assemble it into their chosen design in the kiln, ready to be fired overnight. Helga also taught students the fundamentals about the science of glass: explaining how glass is made; what glass is made from and how technologies have advanced. This was an important part of the course, when we are working with glass, it’s easy to forget the technology, almost magical alchemy involved in such an incredible material.

Cold Working and Wiring

Robin worked with students modifying bases to make them fit. After inspecting the electronic assemblies brought over from Qatar, Robin discovered the battery packs (shipped separately) were just slightly too big for half of the bases, but, no panic, we fetched files (not digital files but metal raspy ones) and sorted! Robin briefed the students about the wiring and coding that would happen. Some of the glass shades were then fitted onto their wired lamp bases and we had our first look at a lamp that glowed! The workshop buzzed like a factory, grinding, sawing, glass cutting, along with shouts from the hot shop. This felt like a hugely successful day as we watched the students gain skills and achieve amazing results.

Day 3 - Wednesday

DAY 3 – WEDNESDAY

All students now understand how to saw and grind off the overblow; how to fit the 3D printed bases properly and how to use ALL of the machinery, including sandblasters, grinders, drills, lathe, linishers, engravers and more. They knew how to cut and fuse glass and how to make beads. Most importantly, all students now had a firm understanding of how glass could be blown into their specific mould and the amount of glass, colour and detail that was required.

Hot Shop

Both blowing benches were put to good use – students knew the moves and all hands were on deck. Each student was now capable of blowing two colour pieces in their two-hour slot. Shouts of “ready” “open”, “close” and “stop”, were a constant and the excitement grew as the teams sped up, repeatedly performing their learned choreographed moves with ease.

Coding and LED

Another group of Students began to work alongside Robin, who was instructing how to program the LED elements of the project. The lamps had to be able to be controlled from an App on their phones. This was a pretty complex project that needed a lot of concentration. Learning the required coding was difficult but the effects it promised were exciting, as students were going to be able to control colour, pattern and speed of the lights. The room started to glow from within the glass, lit from beneath by a circular ring of LEDs – that changed colour.

Cold working and sandblasting

The loud sawing, grinding and cutting was reminiscent of the old glass industry, once so prevalent in the UK, but sadly now in decline – almost extinct. Students now had a few mould blown glass shades that fitted their bases and wanted to experiment with surface decoration, engraving and sandblasting. A realisation that there was only one day left to get the glassblowing completed had triggered a new shift in energy within this hard working, ambitious and polite group of young adults from Qatar.

We finished the day on time and then opened up our studio doors to the glassblowers from Bristol Blue Glass, who had been invited to demonstrate some jaw dropping skills for the group to watch. With food and drinks flowing, they treated us to the most spectacular demonstration of Venetian Goblet making!

DAY 4 – THURSDAY

This was the last day that the hot glass furnaces would be on, and everyone was desperate to get a last go at glassblowing. Putting all of the completed glass pieces on the table, we reviewed the students’ progress, and drew attention to those who needed extra time in the hot shop. We aimed for all students to have at least three pieces that they were happy with and this was their requirement for assessment.

For the students who were happy with the pieces they made – now was the time for cold work.

DAY 5 – FRIDAY

The last day and it was a mad rush to get everyone finished in time and there were a few tears and lots of coffee. A marathon programming session ensued to make sure all fifty-eight lamp bases were up to date with the latest code (Which had been tweaked and improved as week progressed). There were further sessions around the whiteboard teaching students how to drive the app and lights. Finally, we saw all of the lamps put together and lit, with many proud and happy faces before they were packed away for flight home.

MFA ON-THE-GO

Each year students and faculty from the MFA in Design program at VCUarts in Qatar travel together to participate in an immersive learning experience – an annual field study. Students travel outside of their region to benefit from specialized knowledge and innovative processes, while maintaining a cultural link to Qatar through the design outcomes produced. It is a strategic fusion of old and new, students and faculty, foreign and familiar.